In this article, learn how idling at the right RPM protects engine performance and decreases downtime for your turf harvester.

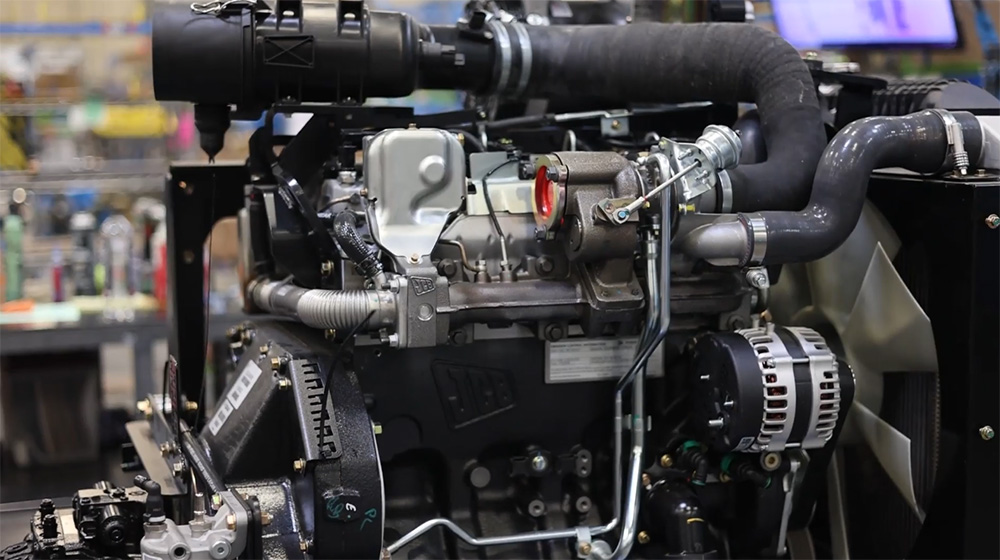

JCB Tier 4 Engine Care

Your JCB Tier 4 engine is designed to deliver reliable power at its proper operating range of 1500–1700 RPM under load. Running in this range not only provides the best performance but also ensures the most efficient fuel consumption.

Problems arise, however, when the engine spends too much time idling at very low RPM. Low idle leads to incomplete combustion, soot buildup, and clogged emissions systems — all of which can shorten engine life and cause downtime.

Why low idle creates problems

Letting your harvester engine idle at low RPM may seem harmless, but it creates incomplete combustion. That leads to soot and unburned fuel collecting inside the engine and exhaust system. Over time, buildup restricts airflow, increases emissions, and can lead to expensive repairs.

The value of higher RPM

When the harvester is stationary, keep the engine running at about 2200 RPM instead of low idle. At this level, the engine maintains proper temperature, which helps the emissions system function efficiently and prevents wet stacking. Think of it as keeping the engine “clean” while it runs.

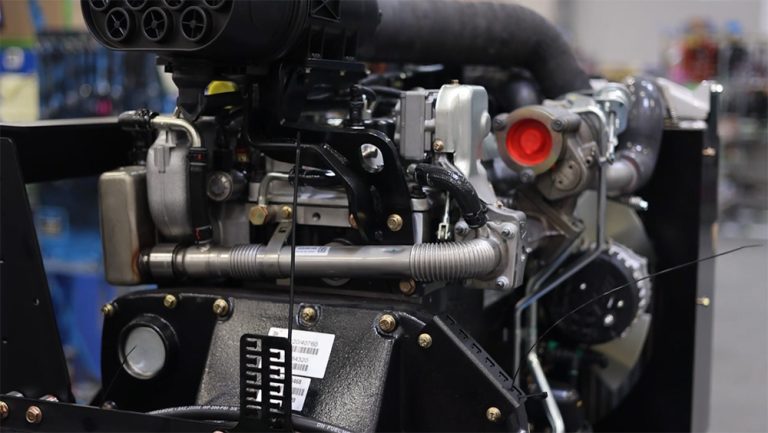

The role of the weekly EGR burn cycle

Your JCB’s exhaust gas recirculation (EGR) system is critical for controlling emissions. To keep it working correctly, run the engine at 2200 RPM for at least one hour each week. Do this during transport or stationary periods, not while working under heavy load.

This weekly routine burns off buildup inside the system and helps prevent clogs or failures. It’s a critical addition to avoiding low idle RPMs.

Regular EGR cooler cleaning

Avoiding low idle RPMs and weekly burn cycles aren’t enough to keep your EGR cooler clean indefinitely. However, the frequency of exhaust gas recirculation (EGR) cooler cleaning depends on engine load.

Engines that run under heavier loads generate enough heat to burn off soot more effectively, reducing the need for cleaning. Lighter-duty operation, on the other hand, lets soot build up faster.

To prevent clogging and keep things running smoothly, clean the EGR cooler every 750–1500 hours, adjusting the interval for how hard the engine has been pushed.

Check out the EGR Cooler Cleaning Process JCB Engine video on our support portal to learn how to properly clean the EGR cooler. (Register for a free support portal account here.)

Best Practices to remember

-

Minimize idle time whenever possible, especially at low RPM.

-

Set engine speed to 2200 RPM when the machine is stationary.

-

Run an EGR burn cycle once per week for one hour at 2200 RPM.

-

Follow the operator’s manual for load-specific guidelines.

These steps are quick and easy to work into your routine, and they go a long way toward extending the life of your engine.

Want more ways to get the most out of your JCB engine?

Check out the JCB Engine System Training Guide: Best Practices & Preventative Maintenance article on our support portal.

(If you haven’t set up your free Support Portal account yet, register here.)