The Maintenance Advantages of FireFly’s AMP Mower

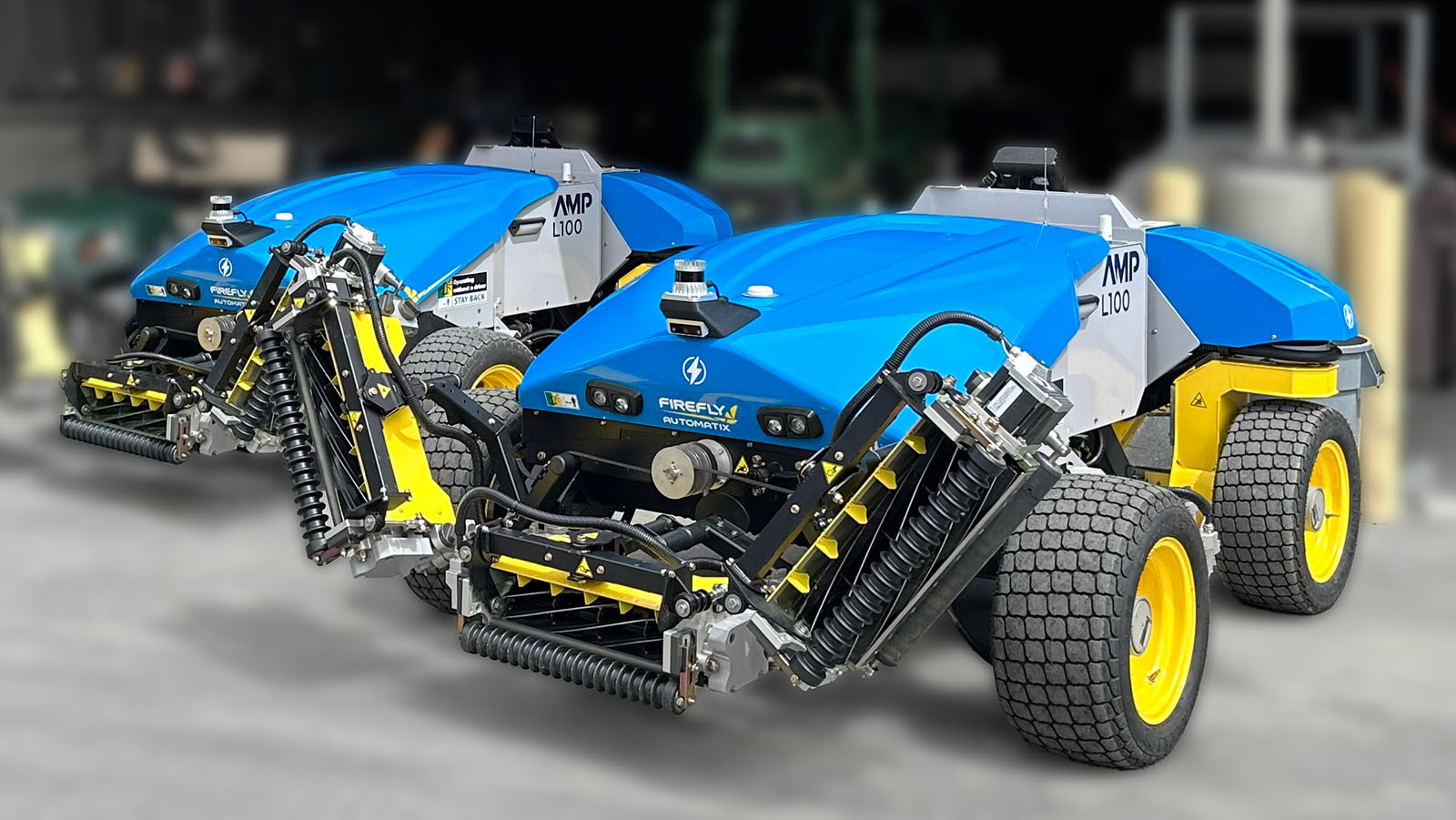

In the realm of turf care, the shift from traditional diesel and hydraulic mowers to the innovative AMP electric mower by FireFly represents a significant leap in efficiency and cost savings. Without an engine or hydraulics, the AMP simplifies and reduces maintenance.

Traditional Diesel and Hydraulic Mower Maintenance

- Engine Maintenance: Diesel engines require regular oil changes, filter replacements, and cooling system checks. These routine tasks are not only time-consuming but also necessitate a stockpile of parts and fluids.

- Hydraulic System Upkeep: Hydraulic mowers are prone to leaks and hose degradation, requiring vigilant monitoring and frequent replacements. Hydraulic fluid changes and the need to address contamination add to the maintenance burden.

- Emission System Care: To comply with environmental standards, diesel engines often have complex emission control systems needing regular checks and maintenance.

- Overall Complexity: The numerous moving parts in diesel engines and hydraulic systems increase the likelihood of breakdowns and the need for repairs, necessitating skilled mechanics on staff.

- Space and Inventory Management: Storing spare parts, fluids, and tools for diesel and hydraulic system maintenance occupies valuable space in maintenance facilities.

The AMP Mower: A Maintenance Revolution

- Electric Motor Reliability: AMP’s electric motors are inherently more reliable and maintenance-free compared to diesel engines. The absence of internal combustion processes and simpler mechanical design leads to fewer points of failure. For example, ground drive motors have been engineered for a 20,000+ hour life, requiring minimal maintenance. Simply change the gear oil every 6 months.

- Maintenance-Free Battery: Unlike diesel engines and hydraulic systems, AMP’s battery is maintenance-free, eliminating the need for regular checks and fluid top-ups.

- Simplified Maintenance Needs: The AMP mower requires minimal maintenance, primarily focusing on adjusting and sharpening the reels – a process simplified by FireFly’s innovative cutting unit design. The only other source of maintenance is checking tire pressure once a week. Our software will also alert you if tire pressure is running low in one or more tires.

- Reduced Need for Skilled Mechanics: With fewer and simpler maintenance tasks, the AMP mower reduces the dependence on skilled mechanics. This translates into cost savings in labor and training.

- Less Space Needed for Spare Parts and Fluids: The electric design of the AMP mower eliminates the need for a variety of spare parts and fluids required for diesel and hydraulic systems, freeing up space in maintenance facilities.

- Enhanced Operational Efficiency: The reliable nature of the electric motor and the maintenance-free battery means less downtime for repairs and maintenance, ensuring consistent operational efficiency.

Conclusion

The AMP mower by FireFly is not just a step towards greener turf care but also a smarter economic choice for businesses. Its electric design significantly cuts down on the time and resources spent on maintenance, compared to diesel and hydraulic mowers. By streamlining maintenance processes and reducing the need for extensive mechanical support, the AMP mower offers an efficient, cost-effective, and reliable solution for modern turf care needs, aligning with both financial and environmental objectives of businesses.