FireFly machines are designed to last. We carefully choose components for durabiity and make design choices to be maintainable for the long haul.

BUILT TO LAST, EASIER TO MAINTAIN

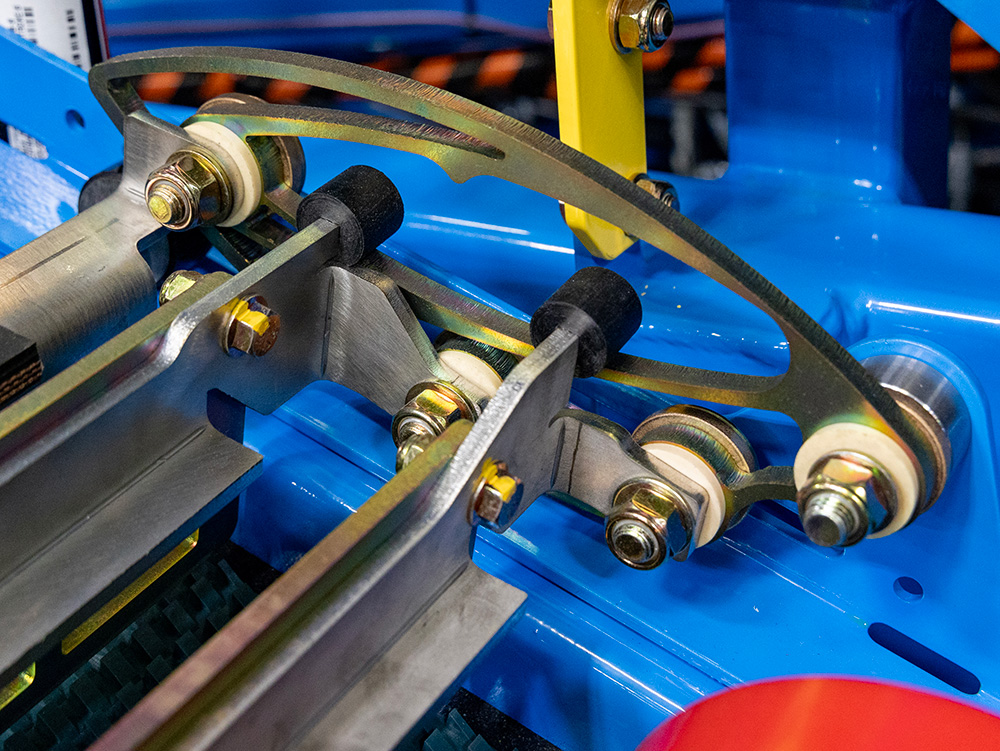

We build our machines with replaceable components, so you could do a major rebuild without having to cut and weld the frame. We never incorporate wear surfaces into major structures that cannot be bolt-in replacements. We also work to make our machine modular. This gives you flexibility for upgrades down the road.

- Class 10.9 flange head bolts used throughout the harvester

- Industry-standard blade arms and connecting rods

- Stainless steel drive shafts with high performance polymer bushings on the stacker for long life and easy service

- Extra wide stacker drive belts provide years of maintenance-free service

- Urethane stacker rollers

- High performance flex cable designed for millions of cycles without wire fatigue

- Hardened alloy steel hooks for reduced breakage

- Heavy pallet magazine bumper resists damage from forklifts

- High quality “Optima” radial cell batteries

- “Top Spin” self cleaning pre-filter

- Proven FireFly rugged sensors

- High quality hydraulic hoses with O-ring face seal fittings less prone to leaks

- Best-in-industry hydraulic filtration continuously filters oil. Ultra-clean oil extends the life of your critical hydraulics.

With every design choice, we strive to reduce your maintenance, and our greaseless bushings save your farm countless hours.

The high-strength polymer material is designed for harsh, dirty environments. Our fittings provide reduced vibration and up to three times longer service life. And perhaps the best part: no maintenance.